Reliable operation in any conditions

Overload switch stops and reverses the gate if a leaf encounters an obstacle during closing. Rubber strip on the leaf front edge protects against damage, when the gate touches an obstacle (e.g. a car)

Photocells stop the gate and return it to an open position if there is any obstacle in driveway

Signalling lamp informs about gate operation

Gate is power supplied with 24V or 230V – in case of any cable damage, there is no threat to person’s life and health

Automatic closing ensures gate self-closing after the programmed period of time. If you forget to close the gate after driving in or out, the gate operator will do it instead of you.

Cover protects the operator against weather conditions, mechanical damages and theft.

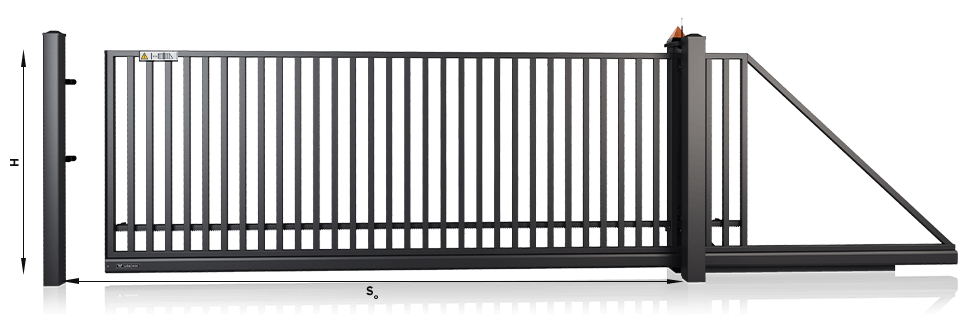

Assembly dimensions and its marking required for sliding gate proper selection and installation – gate opening direction – right, view from the premises side.

So – width between posts (ordering dimension)

H – gate leaf height (ordering dimension)

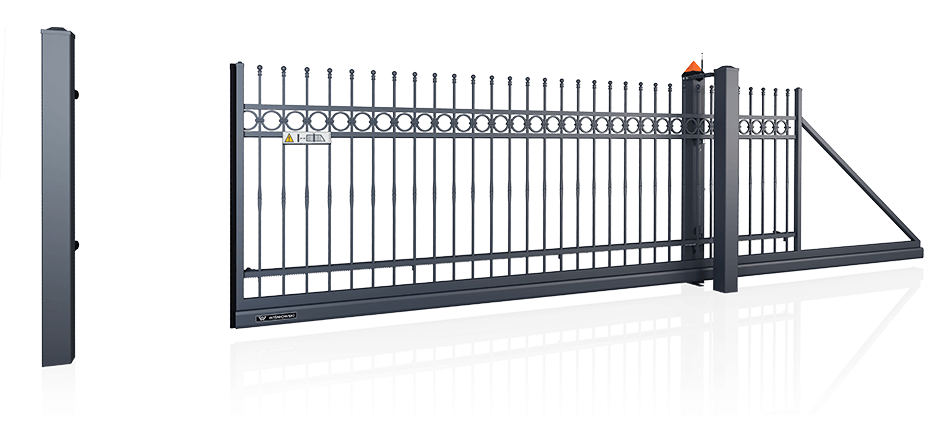

Operator in a post – safe, comfortable and aesthetic solution

Operator installed in a steel post of WIŚNIOWSKI sliding gate is the only such solution in the market.

Instead of external devices which can be stolen or may mar the fence appearance, it is worth ordering the gate with integrated operator.

The post protects the operator against weather conditions.

In case of power failure, the operator can be disengaged, and the gate can be operated manually.

Option with external operator is also available .

All WIŚNIOWSKI fencing system elements are rust-protected with top anticorrosive coating achieved by galvanising and powder painting. It is hot dip galvanising of a chemically cleaned construction that provides dozens of years of rust protection to WIŚNIOWSKI fencing system elements.

All WIŚNIOWSKI fencing system elements are rust-protected with top anticorrosive coating achieved by galvanising and powder painting. It is hot dip galvanising of a chemically cleaned construction that provides dozens of years of rust protection to WIŚNIOWSKI fencing system elements.

Galvanising is an efficient economically technique in terms of both production and maintenance. Galvanised fencing by WIŚNIOWSKI does not require surface maintenance for years. Rust-proofing no longer means expensive treatments as with traditional fencing. Galvanised steel may be recycled so it does not litter or burden the environment.

Galvanising is an efficient economically technique in terms of both production and maintenance. Galvanised fencing by WIŚNIOWSKI does not require surface maintenance for years. Rust-proofing no longer means expensive treatments as with traditional fencing. Galvanised steel may be recycled so it does not litter or burden the environment.

Combined galvanised and varnish coatings in the DUPLEX system make WIŚNIOWSKI fencing serve considerably longer. In all weather conditions WIŚNIOWSKI fencing will look attractive. RAL colour palette application makes a selection of polyester coating colour easy.

Combined galvanised and varnish coatings in the DUPLEX system make WIŚNIOWSKI fencing serve considerably longer. In all weather conditions WIŚNIOWSKI fencing will look attractive. RAL colour palette application makes a selection of polyester coating colour easy.

Galvanising by WIŚNIOWSKI complies with the European norm PN-EN ISO 1461 which guarantees proper quality of galvanised products. Galvanised coating is resistant to both high and low temperatures and UV radiation for best protection of steel surfaces.

Galvanising by WIŚNIOWSKI complies with the European norm PN-EN ISO 1461 which guarantees proper quality of galvanised products. Galvanised coating is resistant to both high and low temperatures and UV radiation for best protection of steel surfaces.

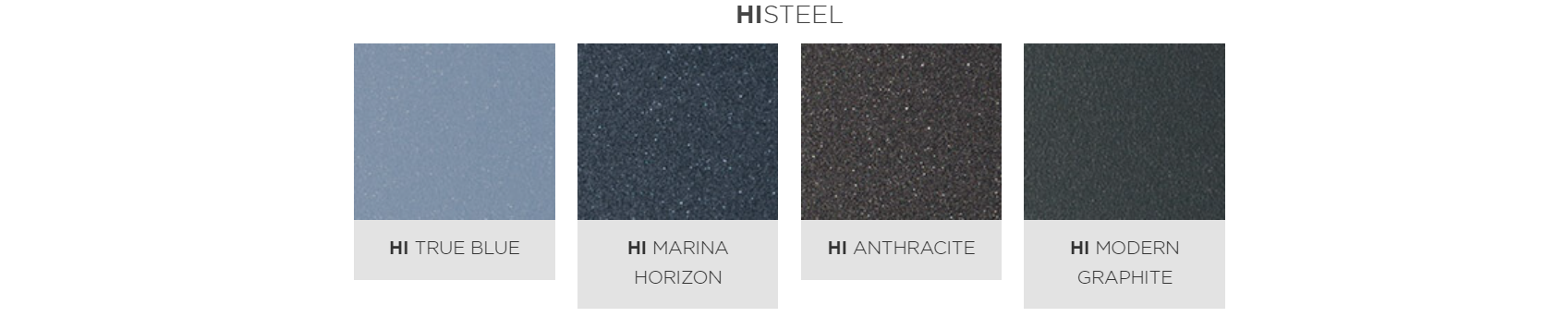

Wide range of colours and designs allows to match fence to facade, door and window joinery and finish elements of the building.

Moreover, powder coating guarantees great aesthetic effect: the surface is free from sagging, it is possible to obtain various decorative effects and different gloss levels.

Comment: Colours and gloss levels shown shall be considered informative only.

Savi 3/2 Pärnu 80010 Estonia