RUBIN metal roofing tile, elegance, minimalist embossing. Available in two variants of module length (350 and 400 mm) and break height (stroke) – 15 / 20 mm. Effective width (covering): 1150 mm.

The shape of the metal roof tile from start to finish was developed by Pruszyński Sp z o. o. taking into account appropriately high aesthetic values while maintaining excellent operational parameters – the covering width of the sheet is 1150 mm!!!

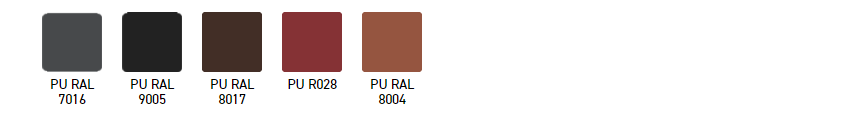

Available Color

0.5mm

polyurethane coating, gloss

Technical specification of the coating

Available Color

0.5mm

Hybrid coating, gloss

Technical specification of the coating

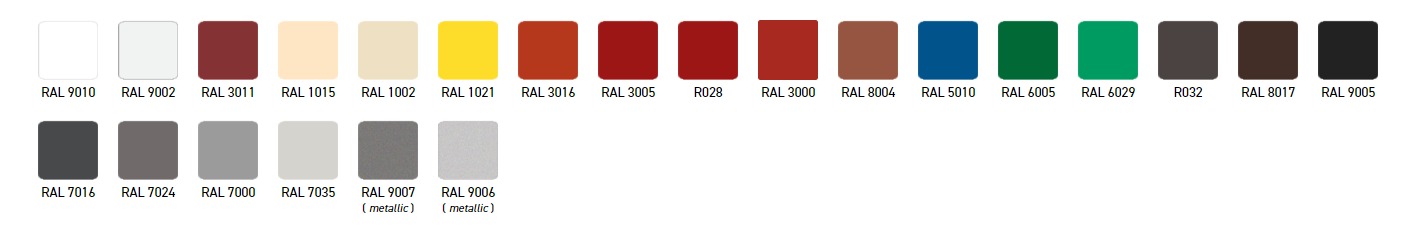

Available Color

Matte polyester

Technical specification of the coating

Available Color

0.5mm

coarse-grained matt polyester

Technical specification of the coating

Available Color

Glossy polyester

Technical specification of the coating

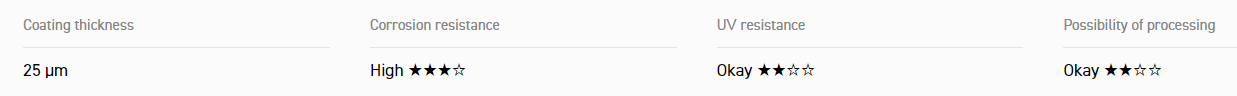

Color Palette

Technical specification of the coating

A special group of colors with a non-standard appearance or composition. Please verify the availability of a given color depending on the coating, as well as the price before ordering.

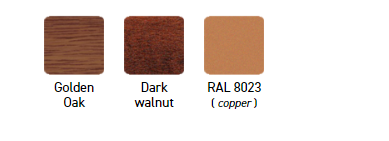

Available Color

| Number of modules | length of sheet – SZAFIR 350/15 | length of sheet – SZAFIR 400/20 |

|---|---|---|

| 2 | 0,8 | 0,9 |

| 3 | 1,15 | 1,3 |

| 4 | 1,5 | 1,7 |

| 5 | 1,85 | 2,1 |

| 6 | 2,2 | 2,5 |

| 7 | 2,55 | 2,9 |

| 8 | 2,9 | 3,3 |

| 9 | 3,25 | 3,7 |

| 10 | 3,6 | 4,1 |

| 11 | 3,95 | 4,5 |

| 12 | 4,3 | 4,9 |

| 13 | 4,65 | 5,30* |

| 14 | 5,00* | 4,7 |

| 15 | 5,35 | 6,1 |

| 16 | 5,7 | 6,5 |

| 17 | 6,05 | 6,9 |

| 18 | 6,4 | 7,3 |

| 19 | 6,75 | 7,7 |

| 20 | 7,1 | 8,1 |

Savi 3/2 Pärnu 80010 Estonia