PWS2-MWA-ST 80, sandwich panel from the WOOLTECH Acoustic line, 80 mm thick, with a mineral wool core with a density of 115 kg/m 3 . Cladding made of coated sheet metal, internal machine perforated.

Wall sandwich panels are used especially in halls, and industrial and public buildings (shopping centers, warehouse centers, sports halls, etc.). In addition to curtain walls, the panels are used as partition walls and as load-bearing walls in small transportable cold stores, construction site facilities and utility buildings.

The acoustic wall sandwich panel is intended primarily for investments requiring the reduction of high noise levels inside the building, by applicable standards, as well as to improve the working conditions of employees. WOOLTECH Acoustic line panels are fully compatible for installation with other sandwich panels produced by Blacha Pruszyński with a visible lock – both with PIR foam core boards and with a wool core, such as PWS2-MW-ST (standard wall sandwich panel), PWS2-MW-EKO (wall sandwich panel with a reduced density core).

Our offer includes acoustic wall sandwich panels with a thickness ranging from 60 to even 240 mm, so we can answer virtually any inquiry requiring high acoustic insulation. It is also worth remembering that acoustic sandwich panels have very good fire resistance parameters. The PWS2-MWA-ST-160 sandwich panel, like others in this line, has a fire reaction class: A2-s1, d0, NRO.

New profile of the connecting contact (lock), tongue-and-groove type. High precision of fit, easy to install. Excellent insulation parameters and reduction of thermal bridges. NOTE – compatibility with PIRTECH boards – allows for free combination of MW2 and PIRTECH boards.

Structural and insulating core, made of the highest quality mineral wool with a density of 115kg/m3 +/- 10%. Mineral wool provides very good insulation parameters, but above all, fire and acoustic insulation. Due to the perforation of the external cladding, it is connected to the cladding using a dedicated adhesive with a precisely defined composition.

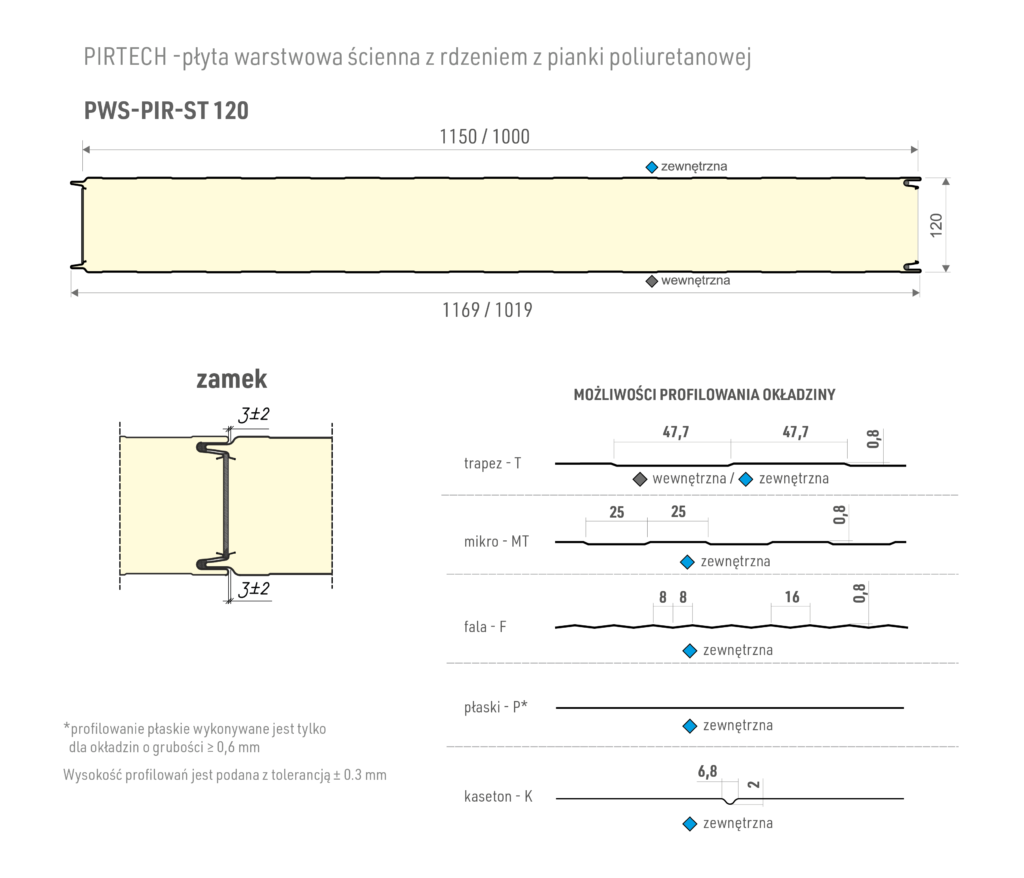

Profiled sheet, 0.5 – 0.7 mm thick, galvanized steel. Permissible profiling: trapezoid (T), micro-trapezoid (MT), wave (F), nano wave (N) and flat (P)*. Protection in the form of varnish and hybrid coatings.

*only for sheet metal thickness ≥ 0.6 mm.

High-quality galvanized steel with a thickness of 0.40 mm – 0.50 mm. Basic profiling and trapezoid. Machine-made perforation for better penetration of sound waves into the mineral wool core. Holes were placed in the strips, leaving space for assembly and fastening of the building’s internal elements. Straps without perforation – provide reinforced hold and stability of the product.

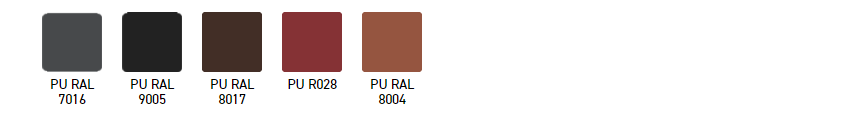

Available Color

0.5mm

polyurethane coating, gloss

Technical specification of the coating

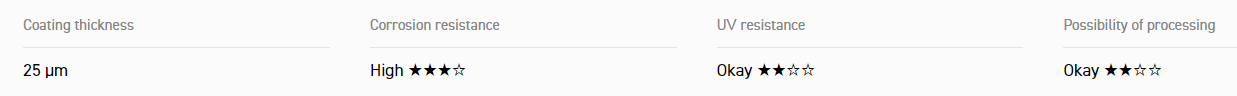

Available Color

0.5mm

Hybrid coating, satin

Technical specification of the coating

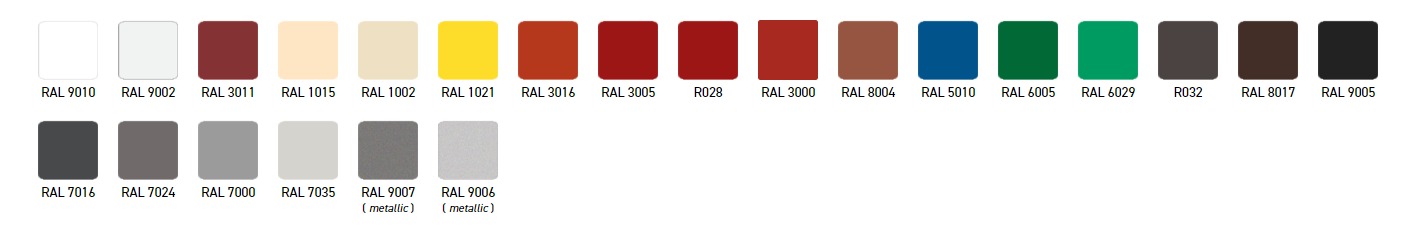

Available Color

0.5mm

Coarse-grained matt polyester

Technical specification of the coating

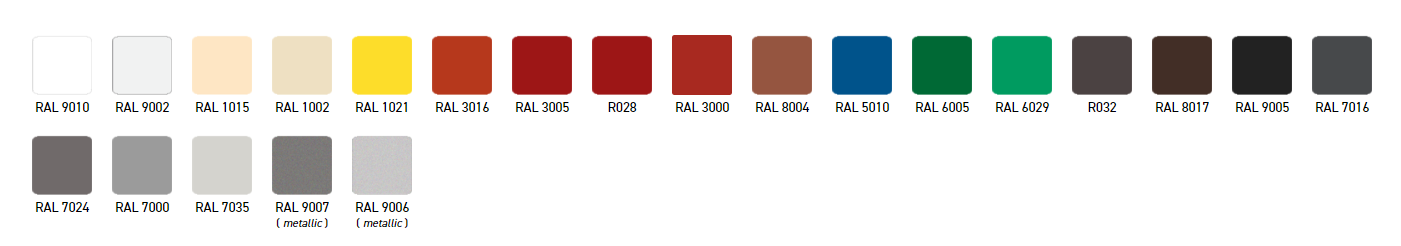

Available Color

0.5mm

Glossy polyester

Technical specification of the coating

Color palette

0.50mm

0.70mm

Base Coatings

Technical specification of the coating

Available Color

1150/1000 mm

| Declared core thermal conductivity coach – [W/mk] | UC heat transfer coefficient – [W/m2K] | UDS thermal insulation [W/m2K] | fire spread / reaction to fire |

|---|---|---|---|

| 0,041 | NPD | NPD | NRO / A2-s1, d0 |

Savi 3/2 Pärnu 80010 Estonia