Wall sandwich panels are used especially in halls, and industrial and public buildings (shopping centers, warehouse centers, sports halls, etc.). In addition to curtain walls, the panels are used as partition walls and as load-bearing walls in small transportable cold stores, construction site facilities and utility buildings.

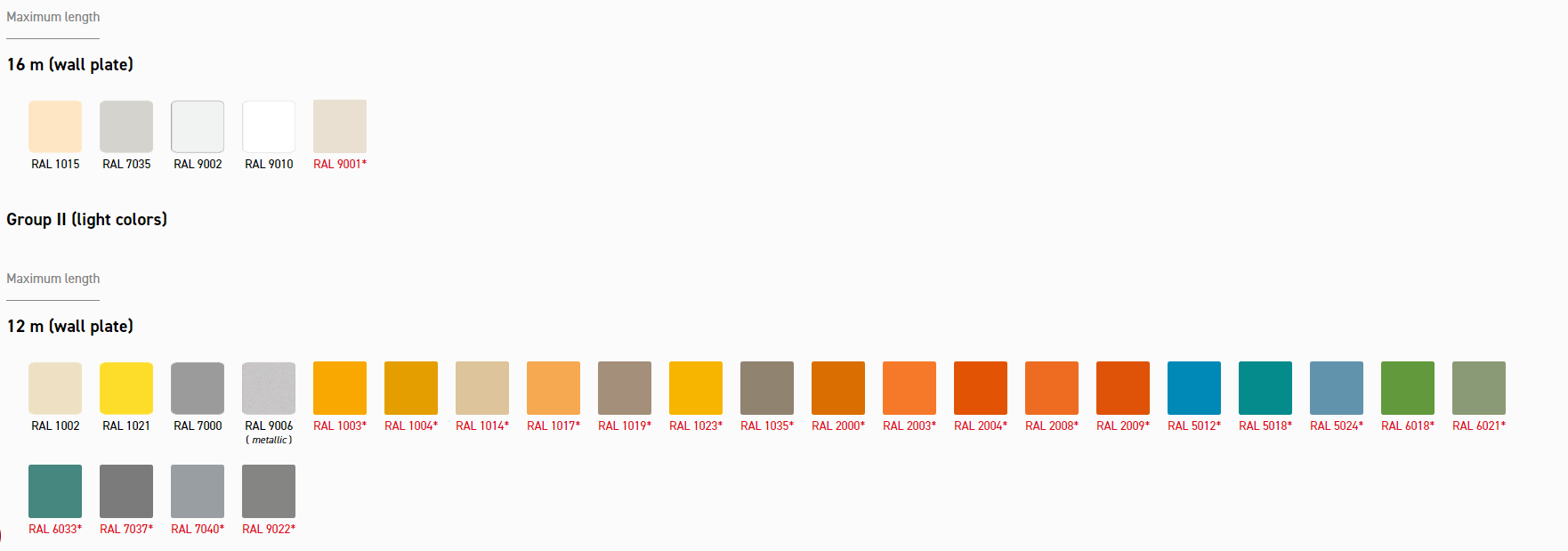

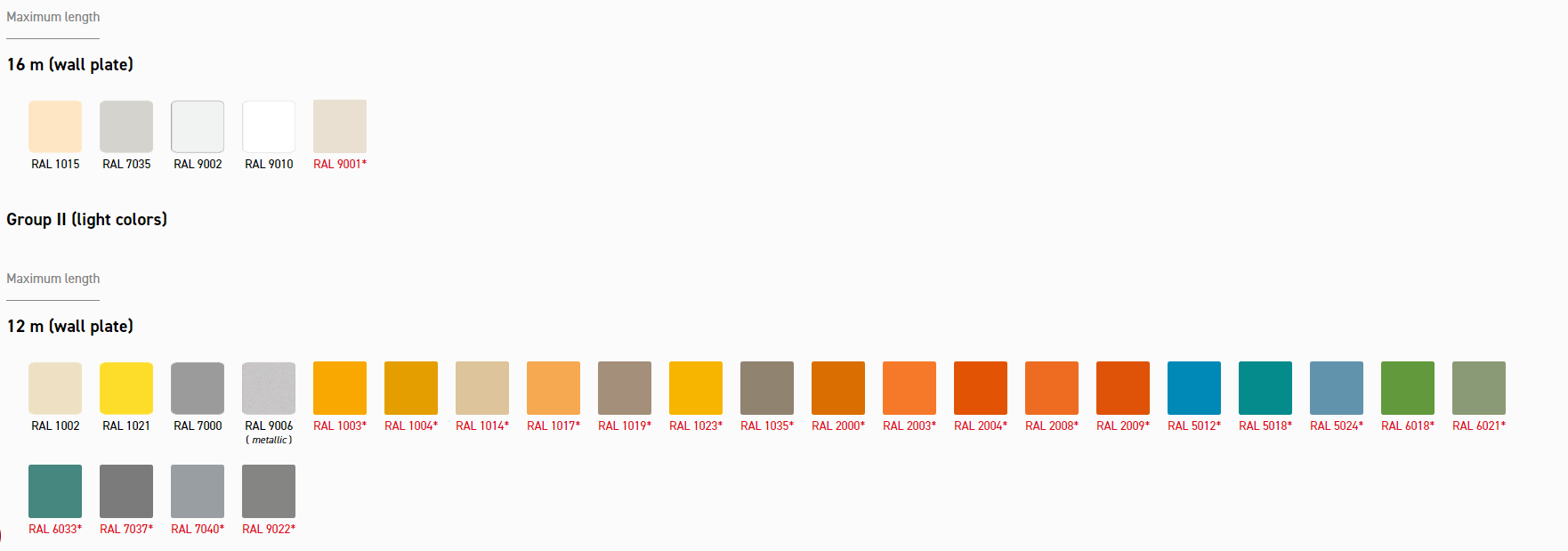

The rich color palette and various shapes of the panels’ profiles enable the creation of several interesting objects. The boards can be mounted both vertically and horizontally.

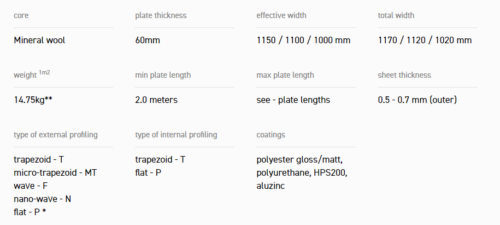

The structural and insulating core is made of the highest quality mineral wool with a density of 115kg/m3 +/- 10%. Mineral wool provides very good insulation parameters, but above all, fire and acoustic insulation. Connecting to the cladding using a two-component polyurethane adhesive.

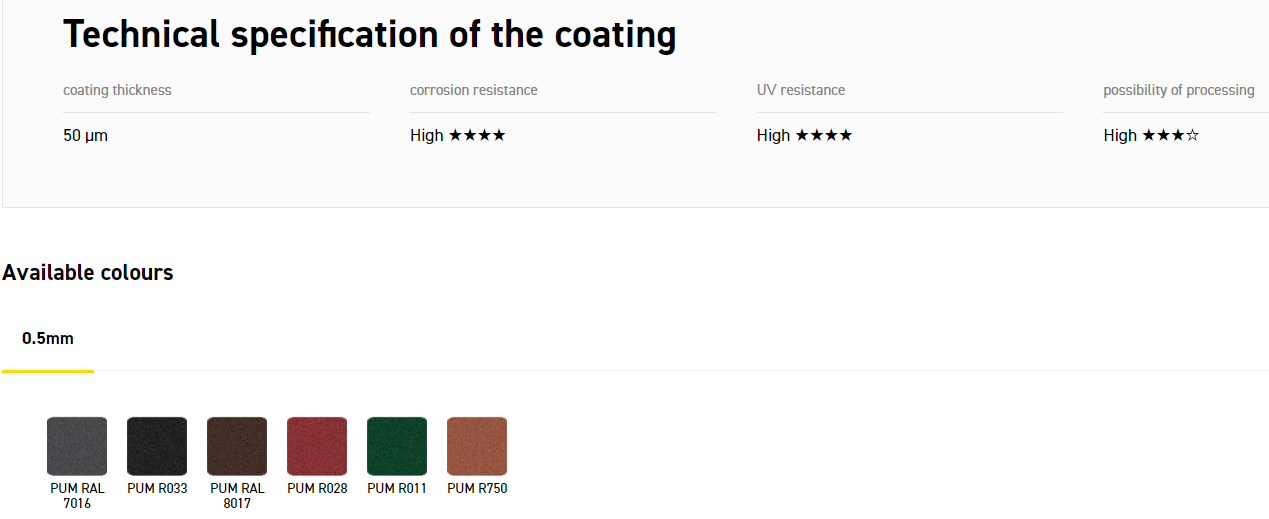

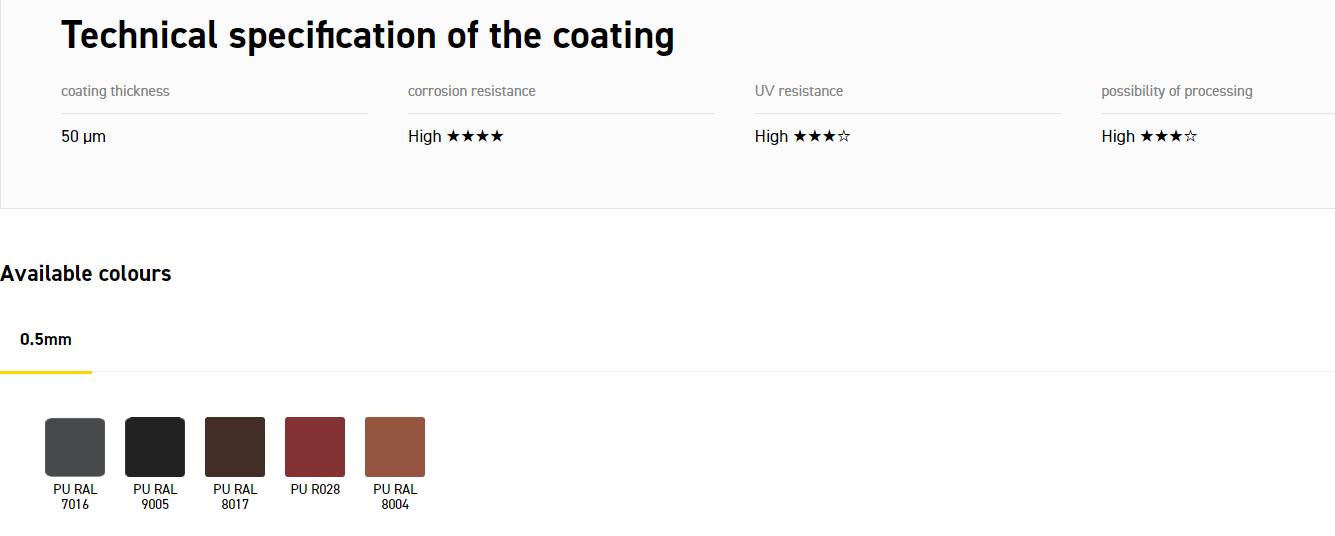

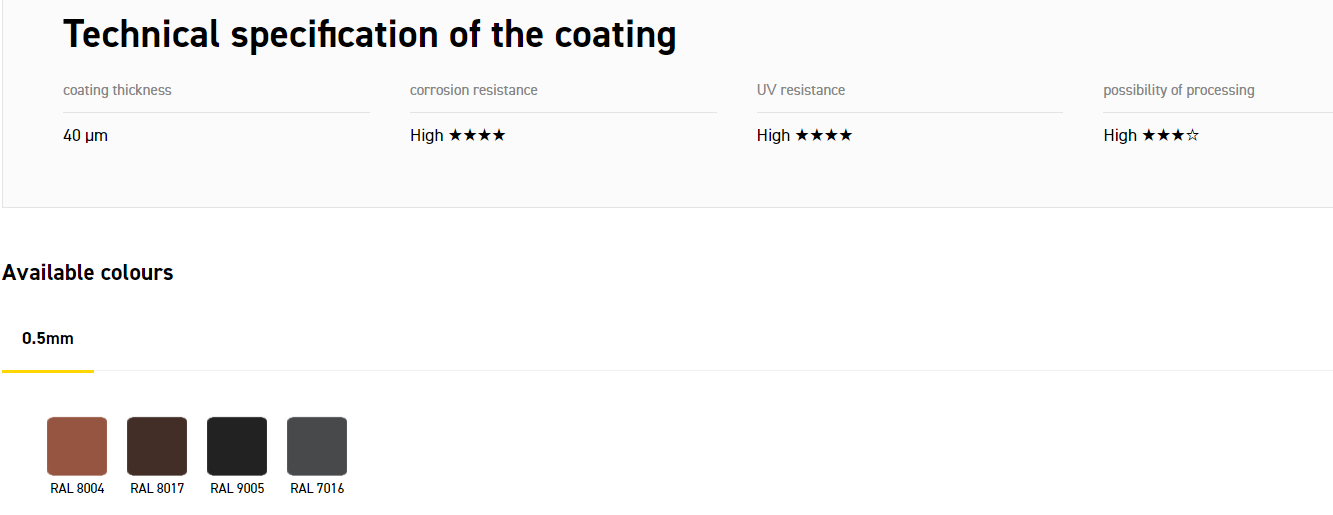

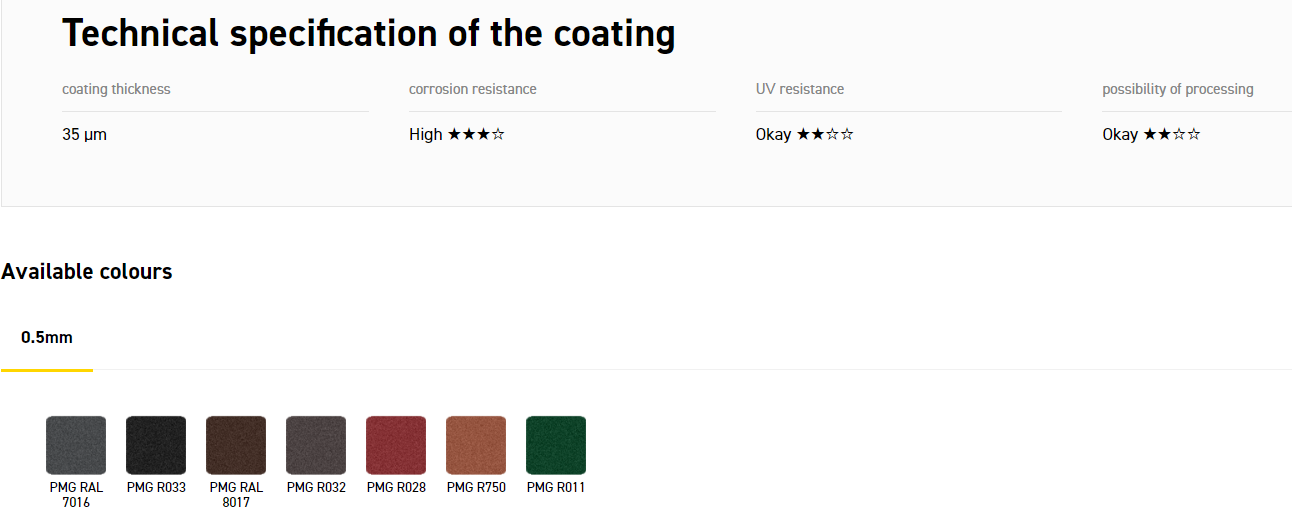

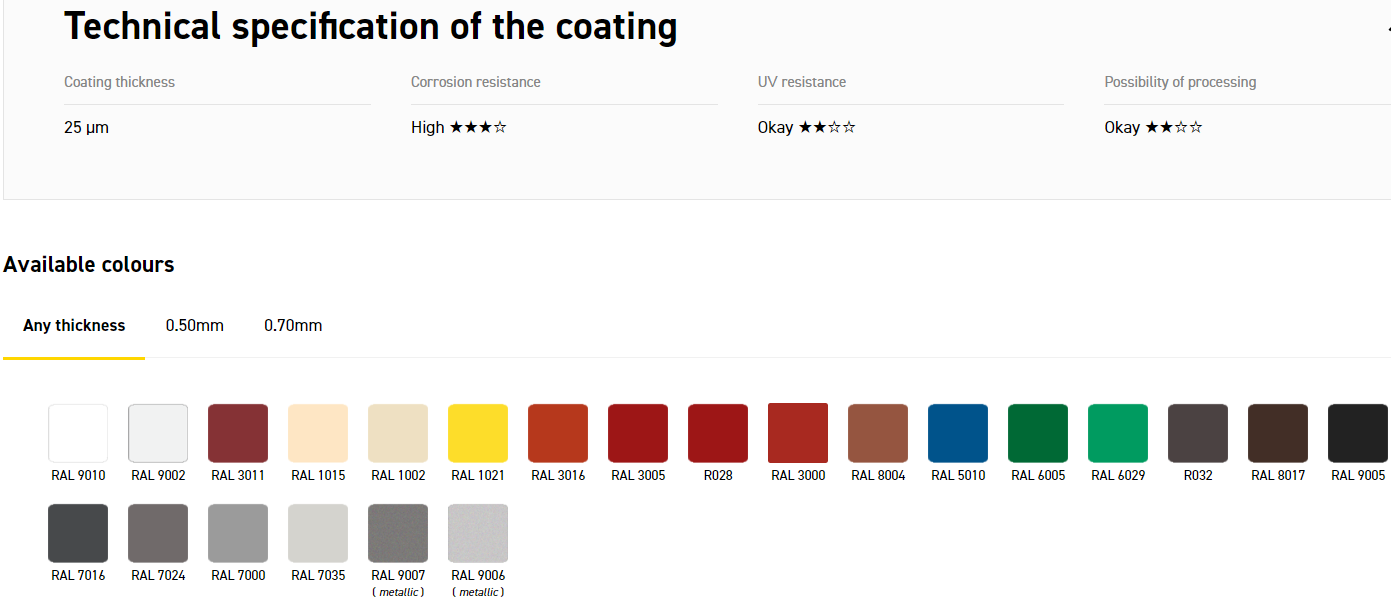

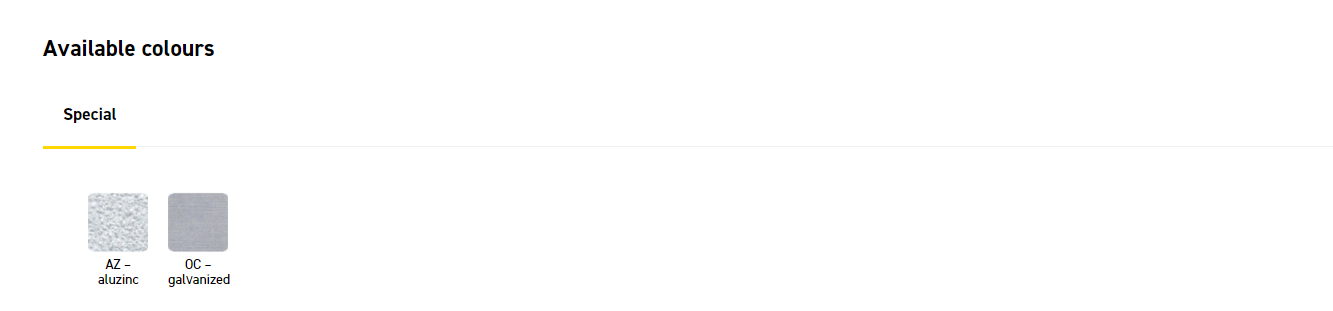

Profiled sheet, 0.5 – 0.7 mm thick, galvanized steel. Permissible profiling: trapezoid (T), micro-trapezoid (M), wave (F), nano wave (N) and flat (P)*. Protection in the form of varnish and hybrid coatings.

*only for sheet metal thickness ≥ 0.6 mm

High-quality galvanized steel with a thickness of 0.40 mm – 0.50 mm. Basic profiling – Trapezoidal (T) profiling is available, possibility of covering with an additional layer of varnish in a selected color, consistent with the available palette.

New profile of the connecting contact (lock), tongue-and-groove type. High precision of fit, easy to install. Excellent insulation parameters and reduction of thermal bridges.

NOTE – Compatibility with PIRTECH boards – allows for free combination of MW2 and PIRTECH boards.

Polyurethane coating, matte

The PWS2-MW sandwich panel is a new, improved generation of our highly rated product on the market – a sandwich panel with a mineral wool core. In the case of a product intended for wall mounting, our offer includes two variants – a plate with a visible lock and a plate with a hidden lock.

Basic features of the product, a sandwich wall panel with a mineral wool core, with a visible lock, 80 mm thick and with a density of 115 kg / m 3

* flat external profiling (P), available only for sheet thicknesses above 0.6 mm

** weight given for *linings with a thickness of 0.5 mm / 0.5 mm.

The table below contains a classification divided into color groups for individual colors available in the Pruszyński Sp. z o. o. Permissible board lengths depending on the color of the cladding (minimum length – 2.5 m) for single-span systems.

The table below contains a classification divided into color groups for individual colors available in the Pruszyński Sp. z o. o. Permissible board lengths depending on the color of the cladding (minimum length – 2.5 m) for single-span systems.

Recommended means of transport for sandwich panels:

Sandwich panels should be stored in packages (posts), a maximum of two packages can be stored on top of each other.

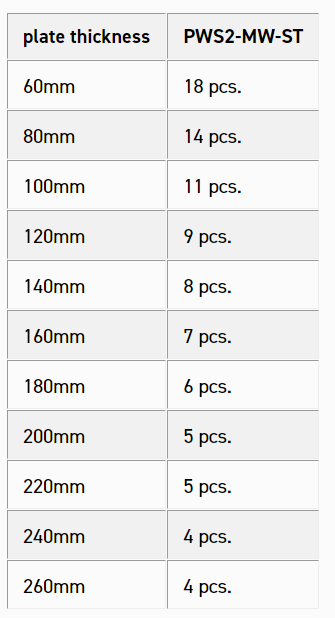

The table below shows the max. the number of boards that can be arranged in one package.

ATTENTION !!!

In the case of wall panels with visible fastening, the upper side of the panels in the package is the façade side, which should be paid special attention!

In order to extend the durability of roofs and facades made of coated sheets, they should be regularly inspected and maintained.

ATTENTION – During inspection, cleaning, maintenance and repairs, health and safety rules must be strictly observed.

The company Pruszynski Sp. z o. o. is not responsible for any accidents resulting from the above activities.

Savi 3/2 Pärnu 80010 Estonia