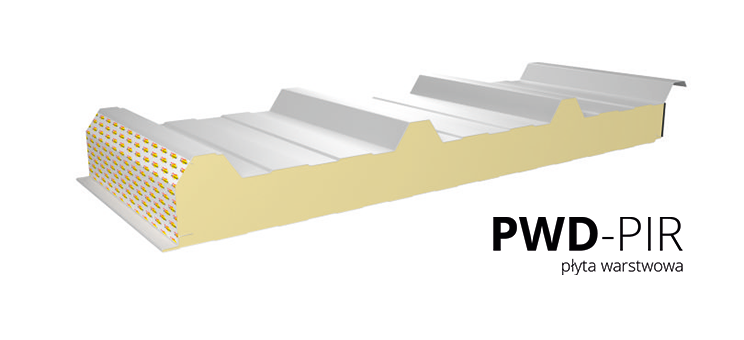

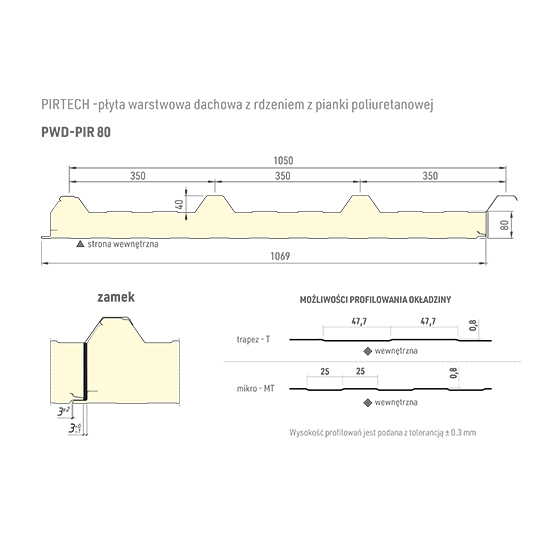

PIRTECH roof panels (visible fastening) with a maximum modular width of 1050 mm allow for simple and quick assembly to various types of structures using clips and appropriate pass-through connectors.

Uniquely designed tongue-and-groove longitudinal joints (locks) ensure very good tightness, fire resistance and quick installation. The shape of the external surface (trapezoidal profile) allows the transfer of high loads and can also be used in single-span and multi-span systems.

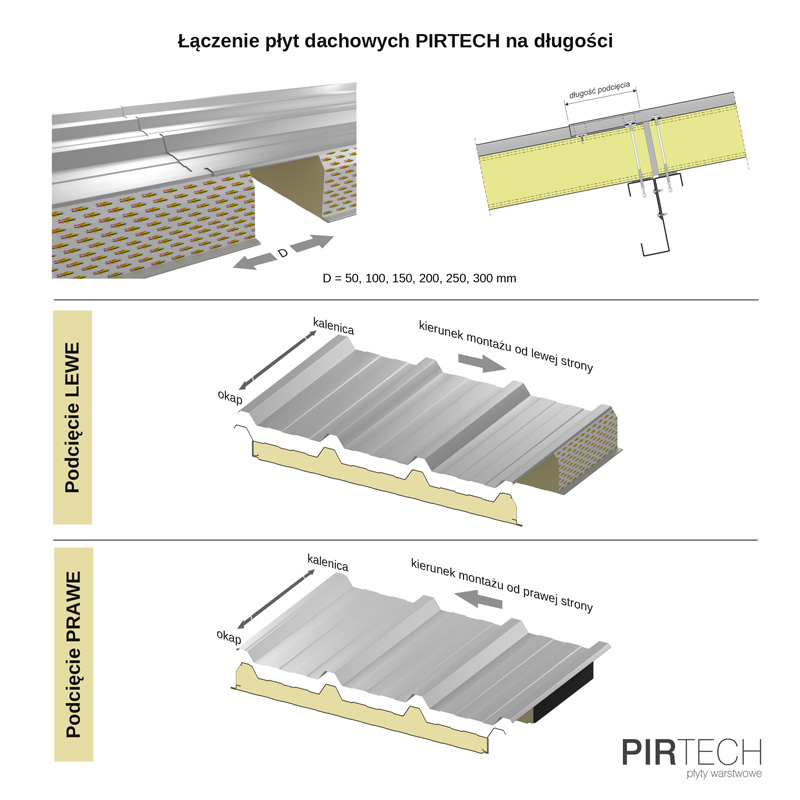

When connecting roof panels lengthwise, it is necessary to cut the upper panel, i.e. the panel on the ridge side.

PIRTECH roof panels can be produced with a ready-made undercut ranging from min. 50 to max. 300 mm.

Just select the type of undercut (see drawing), which is determined by the installation direction:

The undercut length can be D = 50, 100, 150, 200, 250 and max 300 mm.

NOTE: The total board length includes the selected undercut length regardless of its size.

For example, a 6000 mm long board with a 200 mm undercut = 6000 mm (5800 mm core + 200 mm sheet).

The Blachy Pruszynski company makes two types of undercuts:

– full undercut, i.e. cutting the inner sheet, tape on the outer trapezoidal cladding, undercutting the foam across the entire thickness of the board core,

– incomplete undercut, i.e. cutting the inner sheet, undercutting the foam across the entire thickness of the board core.

Individual undercut widths (applies only to the range from 50 to 300 mm) are possible but without a tape on the outer trapezoidal cladding with a foam undercut across the entire thickness of the board core.

For PWD-PIR boards 40, 60, 80, 100, 120 min. the length of the boards with full undercut is 5,000 mm. Boards with lengths below 5,000 mm can only be made without tape on the outer trapezoidal cladding.

For PWD-PIR boards 160 min. the minimum length of boards with full undercut is 4,000 mm. PWD-PIR 160 boards with a length of less than 4,000 mm can only be made without tape on the external trapezoidal cladding.

The production process is carried out continuously on a fully automated line provided by Hennecke, one of the leaders in this industry.

Bulk density: 40.0 kg/m3 ± 3 kg/m3

A unique lock (tongue and groove type) ensures simple and quick installation, additional accessories are available to facilitate the process – calottes and pass-through connectors. The high tightness of the lock ensures very good thermal and fire resistance parameters.

High-quality galvanized steel with a thickness of 0.40 mm – 0.50 mm. Basic profiling – Trapezoidal (T) profiling is available, possibility of covering with an additional layer of varnish in a selected color, consistent with the available palette.

Steel sheet protected with a layer of zinc, covered with one of the organic coatings or an aluminum-zinc coating. Linings made of stainless steel are also available. The basic thickness of the external cladding is 0.50 mm. Thicknesses ranging from 0.40 mm – 0.70 mm are also available. Trapezoidal profiling allows the transfer of high loads and can be used in single-span and multi-span systems.

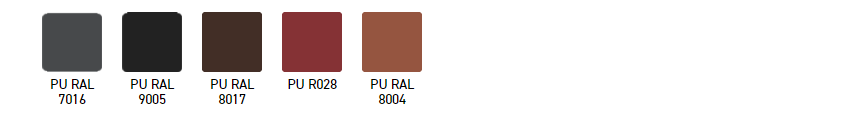

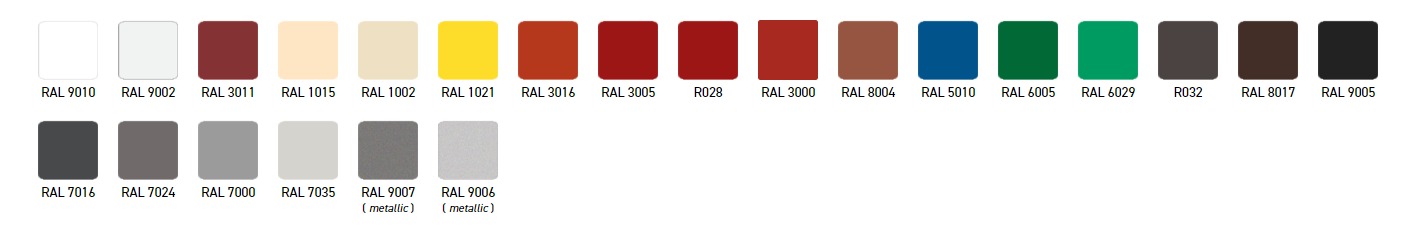

Available Color

0.5mm

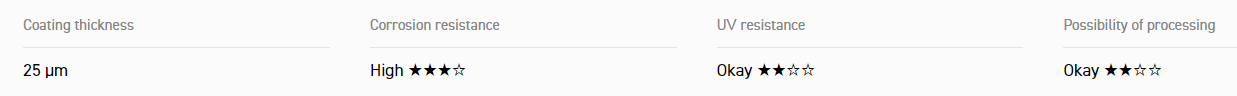

polyurethane coating, gloss

Technical specification of the coating

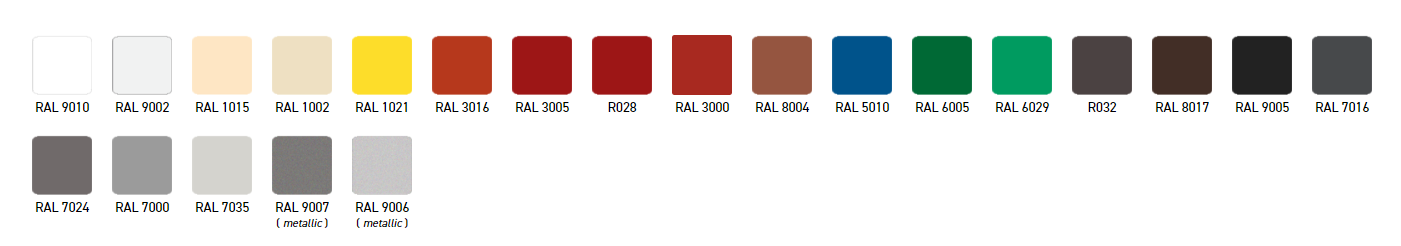

Available Color

0.5mm

Hybrid coating, satin

Technical specification of the coating

Available Color

0.5mm

Coarse-grained matt polyester

Technical specification of the coating

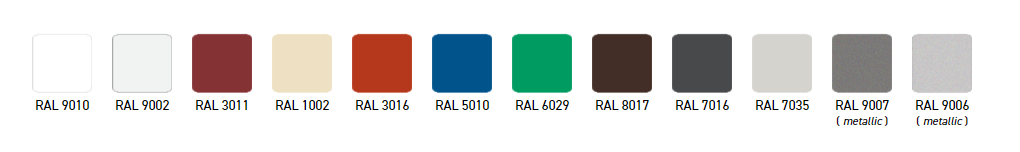

Available Color

0.5mm

Glossy polyester

Technical specification of the coating

Color Palette

0.50mm

0.70mm

Base Coatings

Technical specification of the coating

Available Color

Various thicknesses

0.5mm

1050mm

| Reaction to fire (all usage) | Insulation of sound propagating in the air | Sound absorption | Air permeability |

|---|---|---|---|

| B-s2,d0 | 23(-1;-3) dB | 0,20 | +(C=0.0201, n=0.7506); -(C=0.3664, n=0.5099) |

| Lambda λD coefficient | Coefficient of heat transfer UD,S |

|---|---|

| 0,022 W/mK | 0,22 W/m2K |

Savi 3/2 Pärnu 80010 Estonia