The round metal gutter system offered by our company is a complete drainage system – perfect for any roof, intended for new and renovated buildings, regardless of the type of roofing.

The undoubted advantage of coated steel gutters is their high resistance to mechanical damage.

The use of polyurethane as a protective coating, which has excellent performance parameters (high corrosion resistance and color fastness), ensures reliability for many years. The offered gutters are deeper, so they are able to collect more rainwater without fear of overflow.

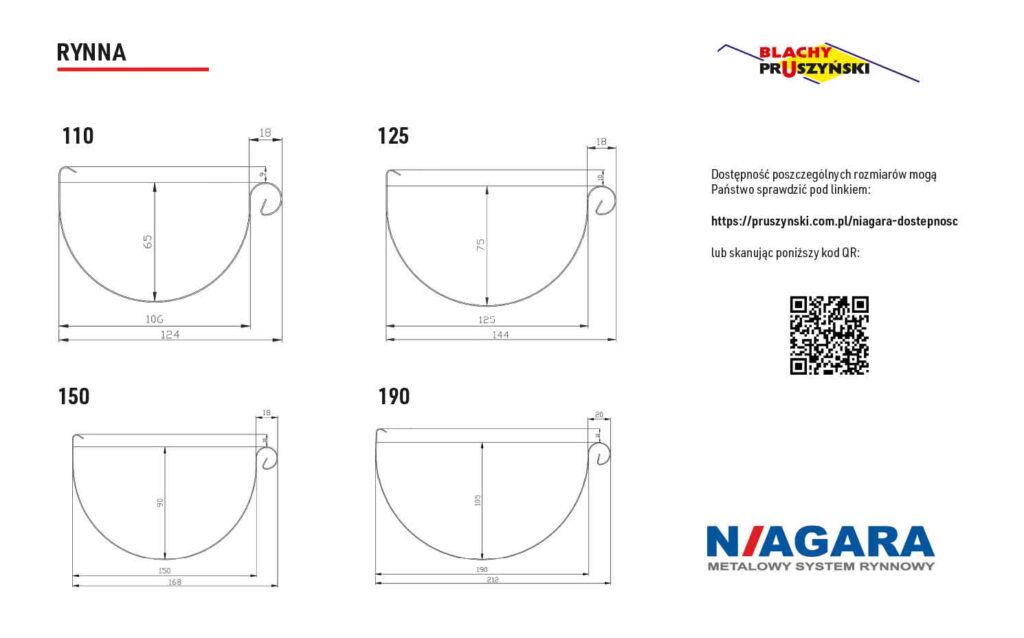

The gutter is the basic element of roof drainage, channeling water flowing from the roof covering into the downpipes. NIAGARA Round gutters are available in several length variants, from 110 to 190 mm in cross-section.

The versatile use of NIAGARA steel gutters makes them available in many configurations, adapted to various types of buildings. The choice of the type of system depends on the type of construction and the roof surface. Depending on the roof surface, two-pipe systems can be used to optimize water drainage efficiency. It is worth noting that not all of our systems are available in all configurations. The following systems offer the widest range of possibilities: NIAGARA Round and NIAGARA Galvanized

All colors of the NIAGARA Round (steel) system are offered in the highest quality polyurethane coatings, which ensure long-term use and reliability. This is especially important in the case of a gutter system that is constantly exposed to long-term effects of water and difficult conditions of use.

Level element of the NIAGARA Stalowa drainage system. Gutters are elements placed directly at the edge of the roof. Thanks to a wide range of mounting components (hooks, connectors, covers, bottoms), it is possible to mount the gutter in several ways, depending on the roof structure. NIAGARA Steel system gutters are made of the highest quality steel and coated with a protective polyurethane coating (50 μm). Thanks to the use of such materials, we can be sure that we obtain color stability and high resistance to weather conditions. Polyurethane is characterized by very high resistance to corrosion and color loss compared to the commonly used PLASTISOL.

| Material | Shell | size(mm) |

|---|---|---|

| Steel sheet min. DX51D+Z with a nominal thickness of 0.64mm Continuously hot-dip coated with metallic coatings | Glossy polyurethane (thickness 50 µm) | Double-sided, organic coating, nominal thickness on both sides of the material | 110 / 125 / 150 / 190 |

Savi 3/2 Pärnu 80010 Estonia