NIAGARA GALVANIZED gutters – a long-awaited product by our customers – is now on sale. The offered system is an economical version of the coated NIAGARA gutters known and appreciated by roofers.

According to the above, NIAGARA ZINC is a product with a more attractive price, while maintaining the main advantages of NIAGARA gutters. The system is available in eight sizes (gutter / pipe). The thickness of the sheet metal from which it is made is 0.6 mm and the zinc layer is 275 g/m²

The versatile use of NIAGARA steel gutters makes them available in many configurations, adapted to various types of buildings. The choice of the type of system depends on the type of construction and the roof surface. Depending on the roof area, two-pipe systems can be used to optimize water drainage efficiency. It is worth noting that not all of our systems are available in all configurations. The following systems offer the widest range of possibilities: NIAGARA Round and NIAGARA Galvanized

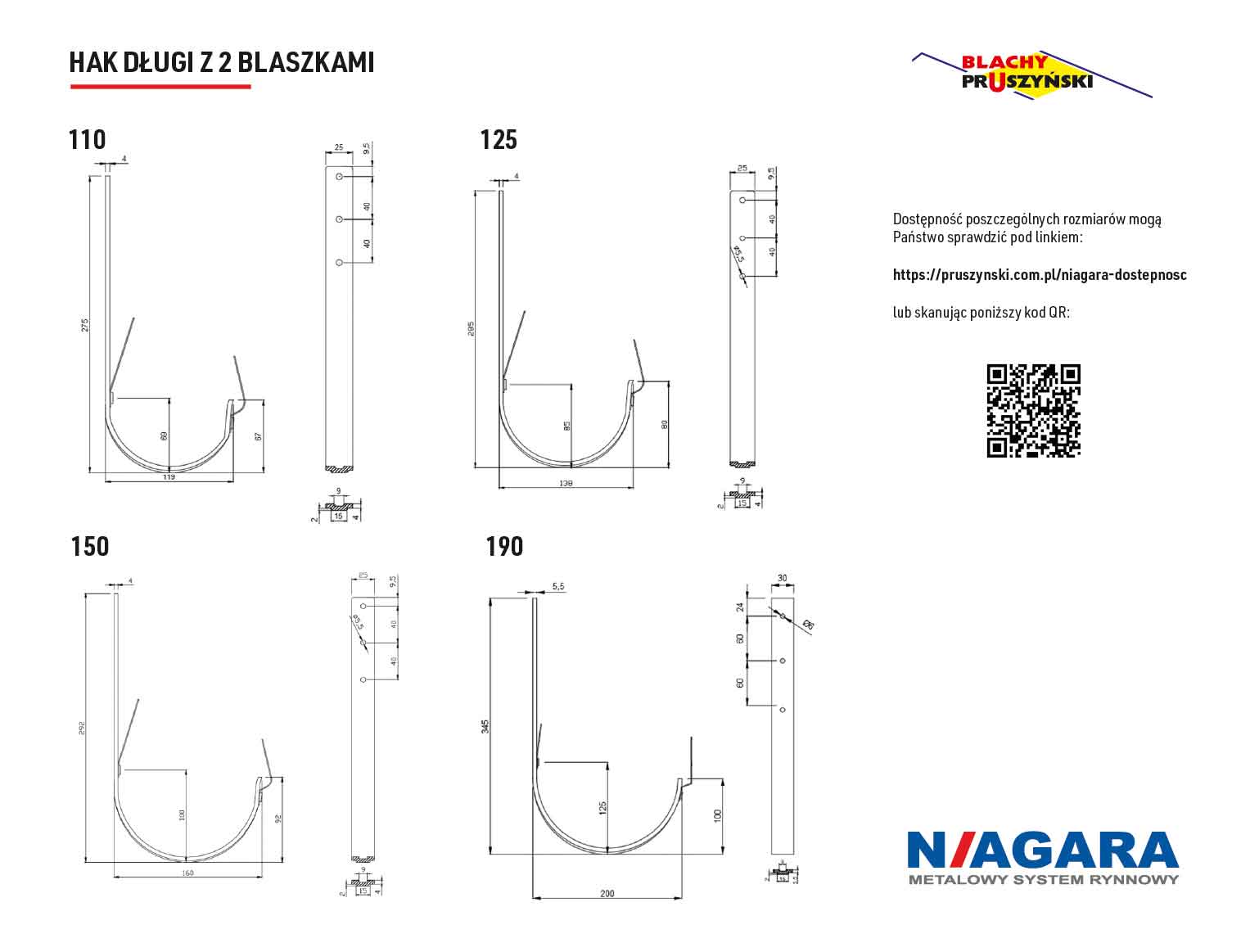

System 110/90

| Size |

| 110

125 150 190 |

Gutters, pipes and other system components should be transported in clean, dry and covered means of transport. They must not be allowed to get wet during transport and storage, as their contact with water may trigger the first stage of the patination process, which is characterized by the formation of a white coating on the surface of the material.

Savi 3/2 Pärnu 80010 Estonia