Our offer includes cassettes with an inclined lock (K2) available to our customers, in two variants of the materials from which they will be made.

Our offer includes cassettes with an inclined lock (K2) available to our customers, in two variants of the materials from which they will be made.

Facade cassettes made of steel are marked KS-2, while those made of aluminum are marked KA-2. Detailed technical parameters are presented in the tables below.

The box with a straight lock ( K1 ) is similarly available in two variants – steel and aluminum.

* Possibility of additional coating with powder-coated varnish

Wooden grate:

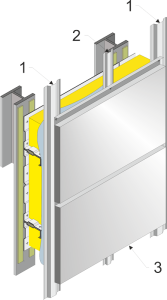

| Aesthetics and functionality as well as the durability of the building materials used are of great importance for every investment. Thanks to the use of increasingly modern products with higher strength and performance parameters, it has become possible to freely use shapes and colors when designing facades, both on individual and industrial buildings. To meet the expectations of its customers, Blachy Pruszyński introduces a new facade development system to the market that fully meets the highest quality requirements, is characterized by universality and rich diversity. |

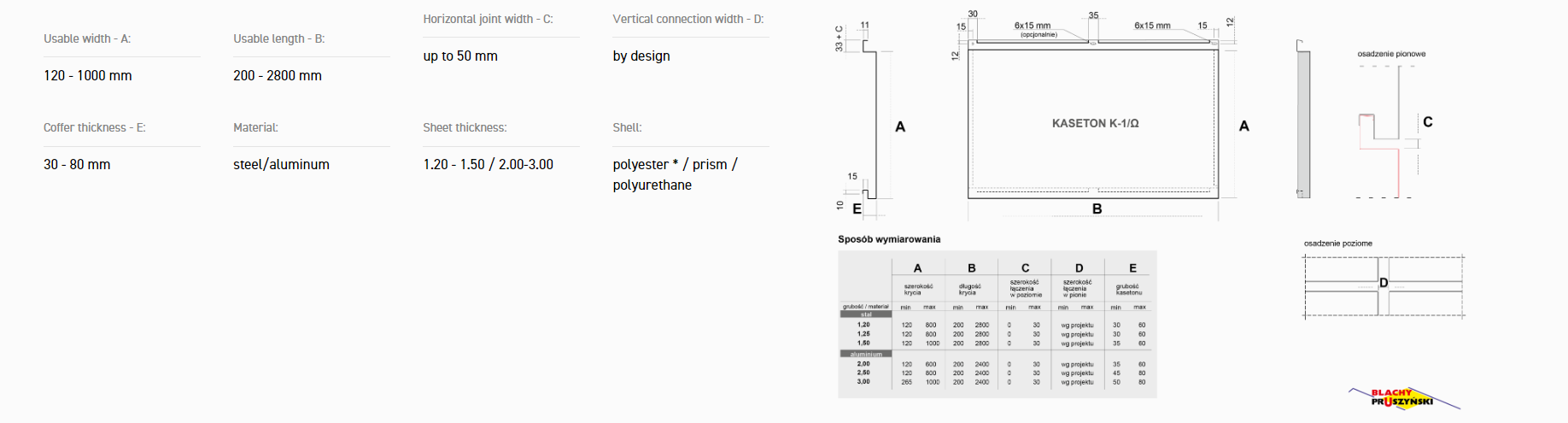

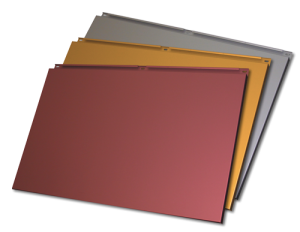

| The Facade Cassette System requires clear marking of the assembly strips to avoid any inaccuracies affecting the tightness and aesthetics of the workmanship. The rich colors of the offered cassettes allow you to manipulate the visual effect and create facades that stand out from the surroundings. The production process and quality control system ensure high precision of workmanship and accurate dimensions, which significantly affects the accuracy and simplicity of assembly. The Pruszyński cassette system is available in a standard version intended for horizontal installation only. The production material used is galvanized coated sheets with a thickness of 1.2 mm to 1.5 mm or aluminum sheets with a thickness of 2.0 to 3.0 mm. The mounting system has been designed to ensure the greatest possible ease and speed of installation while maintaining the durability and tightness of the connections between the individual elements of the system. |

The technical parameters of the system are presented in the table:

| thickness/material | coverage width – A | covering length – B | horizontal connection width – C | vertical connection width – D | coffer thickness – E | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | min | max | min | max | min | max | min | max | min | max |

| steel | ||||||||||

| 1.20 | 175 | 600 | 100 | 2400 | 0 | 50* | by design | 35 | 50* | |

| 1.25 | 175 | 800 | 100 | 2600 | 0 | 50* | by design | 35 | 50* | |

| 1.50 | 175 | 1000 | 100 | 2800 | 0 | 50* | by design | 35 | 50* | |

| aluminum | ||||||||||

| 2.00 | 175 | 900 | 100 | 2400 | 0 | 50* | by design | thirty | 50* | |

| 2.50 | 175 | 1000 | 100 | 2600 | 0 | 50* | by design | thirty | 50* | |

| 3.00 | 175 | 1000 | 100 | 2800 | 0 | 50* | by design | thirty | 50* | |

* – in the case of non-standard dimensions, please contact the Sales Department

For all types of cassettes, the system provides open connections with hidden fasteners. Horizontal joints can be of any width and depend solely on the concept included in the design. Recommended dimensions for vertical joints should be in the range of 10 to 30 mm.

Horizontal joints may have a width depending on the concept included in the design. The standard width is assumed to be from 5 to 30 mm.

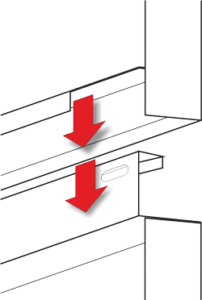

Facade cassettes – fastening technology

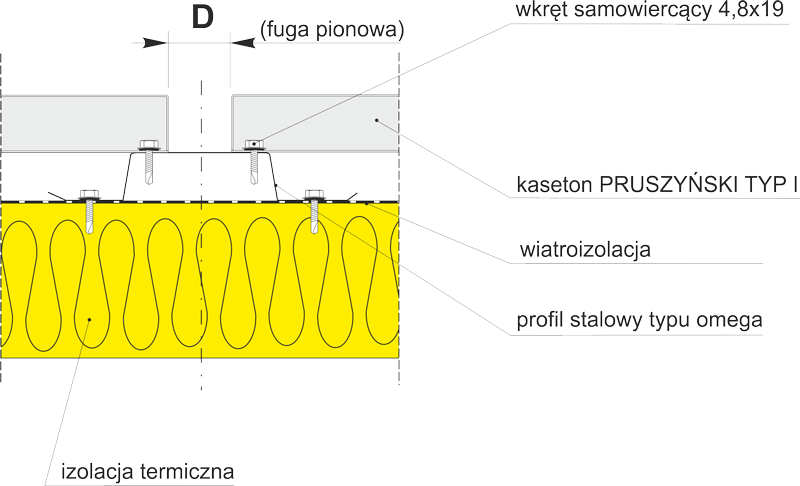

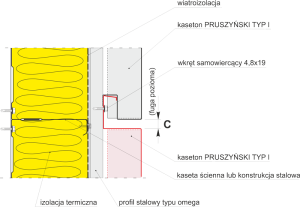

Kaston Pruszynski type I

Vertical joints (D) should be in the range of 10 to 30 mm.

Cross-section through a wall in a light construction

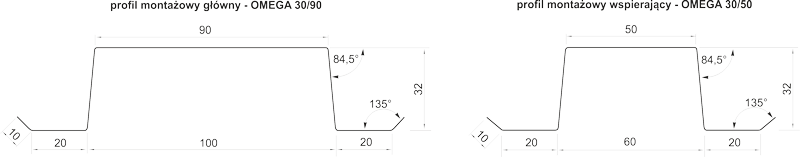

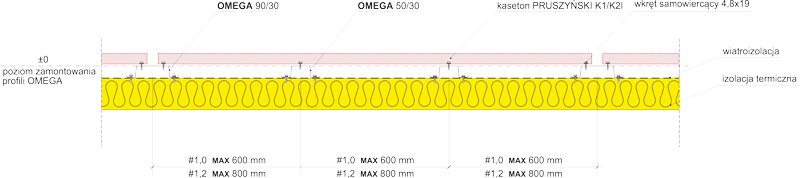

It is recommended to use assembly patches produced by Blachy Pruszyński, type Omega 50, to which individual cassettes are attached using self-drilling screws.

OMEGA 30/90 – made of 0.70 mm thick coated steel sheet in the same color as the OMEGA 30/50 coffer – made of 0.70 mm thick galvanized steel sheet – the so-called supporting profile

Depending on the size of the cassettes, it may be necessary to use a supporting structure. The maximum spacing of intermediate profiles (OMEGA 30/50) is shown below.

In order for the façade to function properly and fulfill its intended functions, it is necessary to use treatments and closures that protect the building against weather conditions and, above all, against rain. The corners are finished using standard system elements with dimensions adapted to the type of cassette. Window edges are sealed using custom-made finishes. In order to ensure proper ventilation of the building, the connections of the cassettes should not be completely tight, natural air circulation should be allowed and water drainage should be allowed.

Colors are made individually to order.

Savi 3/2 Pärnu 80010 Estonia