Cold-formed structural profiles of the C+ and Σ+ types are a new proposition in the Blacha Pruszyński offer for customers who are looking for a solution with even greater load-bearing capacity.

Cold-rolled sections are a proven and effective construction solution. In our offer, in addition to the standard profiles – Z , C and Σ , we also offer “+” profiles. Thanks to the use of a wider material input, as well as a modern and advanced production line, we are able to introduce additional profiling at the ends of the section – the so-called moustache. The C+ profile, like Sigma+ , is aimed at architects and investors who need increased load-bearing parameters. In particular, the C+ profile, whose universal shape is based on the C profile, appreciated by our customers, offers the same perforation possibilities and cross-section, while also increasing its load-bearing capacity compared to the base version, thanks to the characteristic “whiskers”.

A wide variety of strength parameters of sections allows for optimal selection of the amount of material needed – we encourage you to familiarize yourself with the full offer of our cold-rolled sections

Metallic coatings –

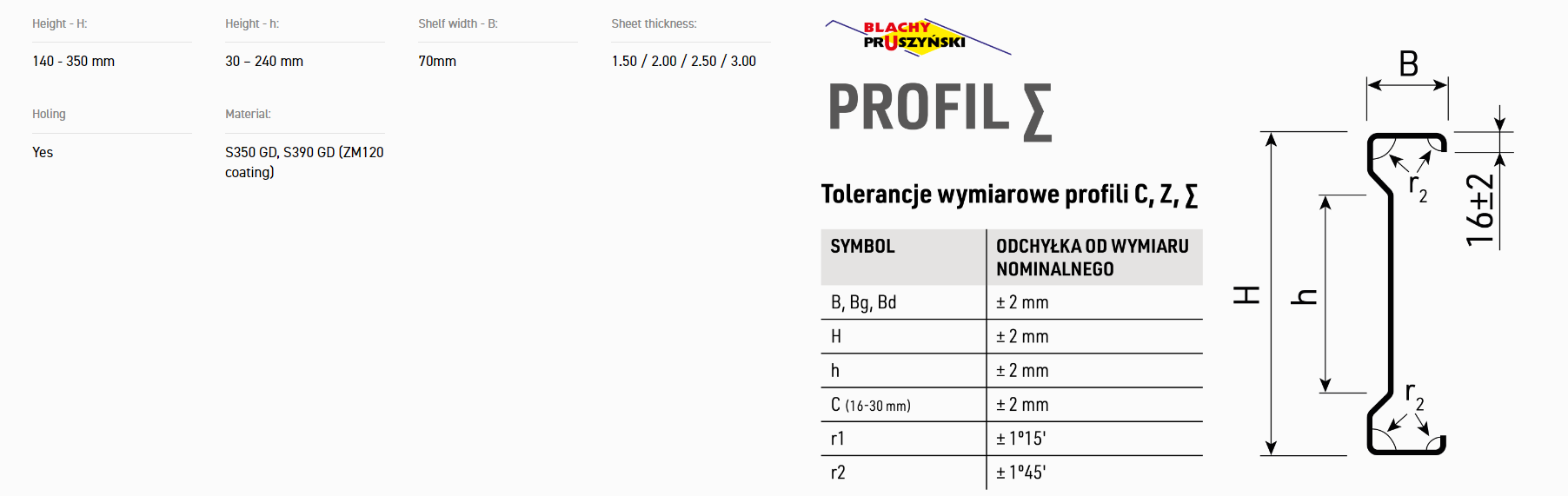

Technical details and parameters of cold-formed sections type: Σ. They are made of high-quality S350 GD or S390 GD steel (on request). They have a specially developed profile which, thanks to appropriate bends, offers increased load-bearing parameters, even when using a lower thickness of the input material. NOTE Purlins with a Σ profile can use sheet metal up to 3.0 mm thick. Variant with “whiskers” – Σ+ type section, can use sheet metal up to a maximum thickness of 2.5 mm

| PROFILE C+ | thickness | Libra | H | B |

|---|---|---|---|---|

| mm | kg/m | mm | mm | |

| C+ 200 | 1.50 | 4.80 | 200 | 69 |

| 2.00 | 6.40 | 200 | 72 | |

| 2.50 | 8.00 | 200 | 75 | |

| C+ 250 | 1.50 | 5.64 | 250 | 79 |

| 2.00 | 7.52 | 250 | 82 | |

| 2.50 | 9.32 | 250 | 83 | |

| C+ 300 | 2.50 | 10.32 | 300 | 83 |

| C+ 350 | 2.50 | 11.32 | 350 | 83 |

| C+ 400 | 2.50 | 11.68 | 400 | 67 |

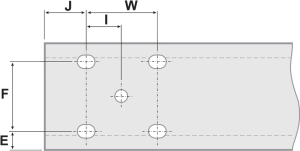

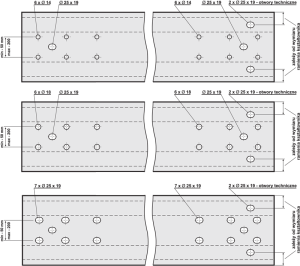

“C” and “C+” profiles enable quick and easy development of industrial or service halls. They are connected mainly with screws. For this purpose, three types of holes are provided in the profiles (table 1):

Table 1.

| Round holes (diameter – Ø in mm) | Bean holes (length x width – in mm) |

|

|

|

|

|

|

| |

| |

|

Depending on the type of profile used, there are different values for the spacing of technical and assembly holes. Their values are given in the table above.

The drawing shows the possibilities of longitudinal drilling.

Opening is possible in all planes of the section.

E – dimension from the wide shelf Bg (for Z profile)

Hole arrangement

| C+ profile | sheet thickness | E | F |

|---|---|---|---|

| mm | mm | mm | |

| C+ 200 | 1.5 | 50 | 100 |

| 2.0 | 50 | 100 | |

| 2.5 | 50 | 100 | |

| C+ 250 | 1.5 | 50 | 150 |

| 2.0 | 50 | 150 | |

| 2.5 | 50 | 150 | |

| C+ 300 | 2.5 | 50 | 200 |

| C+ 350 | 2.5 | 50 | 250 |

| C+ 400 | 2.5 | 50 | 300 |

The types and arrangement of holes in Z/C sections are basically any and we present them in sample drawings.

Types and arrangement of holes – c profile

Savi 3/2 Pärnu 80010 Estonia