Cold-formed construction profiles of the Z, C, Σ and U types are made of cold-rolled steel.

Cold-rolled sections are a proven and effective construction solution. Our company’s basic offer in this area consists of sections (purlins) with Z, C, Σ and U profiles. Additionally, thanks to the launch of a new production line, we have expanded our offer to include C+ and Σ+ profiles. The cold-formed U-type profile is aimed at customers who are looking for a slightly cheaper solution, and the construction needs resulting from the investment project are not so demanding. In particular, the U-shaped section, thanks to the narrower tape from which it is made, is slightly more economical in terms of material consumption. However, it offers slightly lower load-bearing parameters. Therefore, it is a very good solution for buildings where the loads are not so high.

A wide variety of strength parameters of sections allows for optimal selection of the amount of material needed – we encourage you to familiarize yourself with the full offer of our cold-rolled sections

Metallic coatings

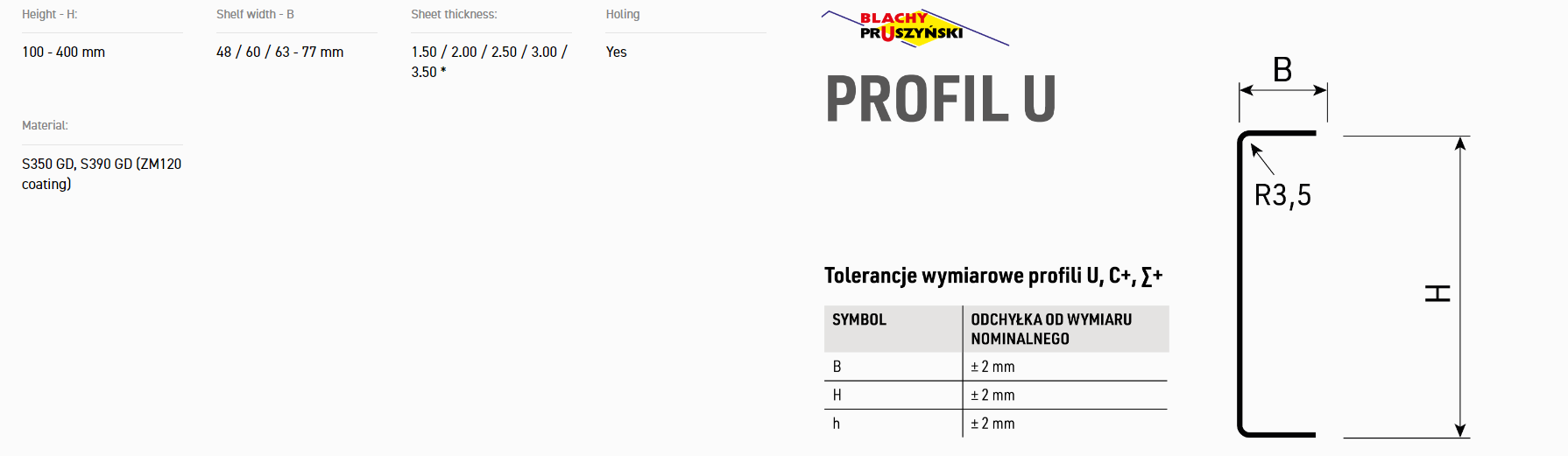

Technical details and parameters of cold-formed sections type: U. U purlins are a new proposition in our offer of sections. They are made of high-quality S350 GD or S390 GD steel (on request). They are made of a narrower steel strip, which affects the cost aspect of the investment. Like our other shapes, they offer extensive drilling options – details below.

| PROFILE U | sheet thickness | Libra | H | B |

|---|---|---|---|---|

| mm | kg/m | mm | mm | |

| U 100 | 1.50 | 2.57 | 100 | 60 |

| 2.00 | 3.39 | 100 | 60 | |

| 2.50 | 4.20 | 100 | 60 | |

| 3.00 | 4.99 | 100 | 60 | |

| 3.50* | 5.77 | 100 | 60 | |

| U 150 | 1.50 | 2.88 | 150 | 48 |

| 2.00 | 3.81 | 150 | 48 | |

| 2.50 | 4.72 | 150 | 48 | |

| 3.00 | 5.62 | 150 | 48 | |

| 3.50* | 6.50 | 150 | 48 | |

| U 150 | 1.50 | 3.17 | 150 | 60 |

| 2.00 | 4.19 | 150 | 60 | |

| 2.50 | 5.20 | 150 | 60 | |

| 3.00 | 6.19 | 150 | 60 | |

| 3.50* | 7.17 | 150 | 60 | |

| U 200 | 1.50 | 3.50 | 200 | 48 |

| 2.00 | 4.64 | 200 | 48 | |

| 2.50 | 5.76 | 200 | 48 | |

| 3.00 | 6.86 | 200 | 48 | |

| 3.50* | 7.95 | 200 | 48 | |

| U 250 | 1.50 | 4.51 | 250 | 65 |

| 2.00 | 5.98 | 250 | 65 | |

| 2.50 | 7.44 | 250 | 65 | |

| 3.00 | 8.83 | 250 | 65 | |

| 3.50* | 10.25 | 250 | 65 | |

| U 300 | 1.50 | 5.28 | 300 | 73 |

| 2.00 | 7.04 | 300 | 74 | |

| 2.50 | 8.80 | 300 | 75 | |

| 3.00 | 10.56 | 300 | 76 | |

| 3.50* | 12.32 | 300 | 77 | |

| U 350 | 1.50 | 5.66 | 350 | 64 |

| 2.00 | 7.52 | 350 | 64 | |

| 2.50 | 9.36 | 350 | 64 | |

| 3.00 | 11.18 | 350 | 64 | |

| 3.50* | 12.99 | 350 | 64 | |

| U 400 | 2.50 | 10.32 | 400 | 63 |

| 3.00 | 12.34 | 400 | 63 | |

| 3.50* | 14.34 | 400 | 63 | |

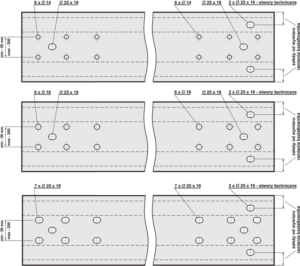

The “U” profile allows for quick and easy development of industrial or service halls. They are connected mainly with screws. For this purpose, three types of holes are provided in the profiles (table 1):

Table 1.

| Round holes (diameter – Ø in mm) | Bean holes (length x width – in mm) |

|

|

|

|

|

|

| |

| |

|

The types and arrangement of holes in U-shaped sections are basically any and we present them in sample drawings.

Types and arrangement of holes – U profiles

Savi 3/2 Pärnu 80010 Estonia